Okwamanje,izigaba ezintathu zokungenisa i-ac motorizintambo zokuhola zimelela isici esibalulekile sokumiswa kukagesi womkhiqizo wemoto, okuhlanganisa izizinda zokuhlukanisa ugesi kanye nezindaba zokuqhuba. Ngokombono, inqobo nje uma ukukhetha nokufakwa kokuminyana kwamanje kuhambisana nezinkambiso ezifanele, ingxenye yentambo eholayo ngeke ize yethule noma yiziphi izinkinga ezihlobene nokushisa. Kodwa-ke, ekusebenzeni, izimo zalolu hlobo lwenkinga zenzeka, futhi ukuze uthole ukuqonda okujulile kwezimbangela eziyinhloko, kuyadingeka ukuhlola izici ezithile zokwehluleka okukhulunywa ngakho.

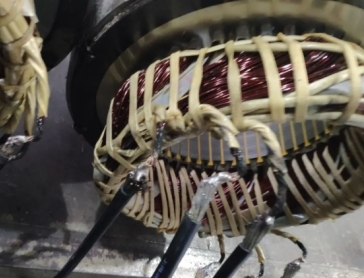

(A). Zonke izintambo zokuhola zibonisa izimpawu zezinkinga ezihlobene nokushisisa. Ekubhekaneni nalolu daba, ukugxila kwethu kusekuhambisaneni nobubanzi kanye nokwakheka kwezinto zekhondatha yocingo oluholayo. Uma kwenzeka le nkinga iphakama, kungenzeka ukuthi akuyona nje indaba yamaphutha okufakwa ngakunye, kodwa inkinga yesistimu ethinta amayunithi amaningi. Lolu hlobo lwenkinga lungabangelwa ikhwalithi yenqubo yokukhiqiza izimoto.

(B). Izinkinga zokushisisa izintambo eziholayo ngazinye. Le nkinga iyisici esivame kakhulu sephutha esiye sabikwa ngesikhathi sokusebenza kwei-induction motor. Ezimweni eziningi, leli phutha libuye lihambisane nenkinga yokukhishwa kwebhodi elibulalayo. Ukuhlaziywa kwamacala amaphutha angempela kuveza ukuthi le nkinga ibangelwa ukungaxhunywanga kahle kwendawo kwentambo yomthofu. Ingase yenzeke endaweni yokuxhumana phakathi kolayini oyinhloko ojikayo wemoto kanye nentambo eholayo, futhi ivame ukubonwa lapho kulungiswa intambo yokuhola yemoto kanye netheminali, noma isixhumanisi sokulungisa phakathi kwetheminali nebhodi letheminali.

(C). Ukushisa okuphawuliwe kungabangelwa ukusebenza kwe-low-voltage. Lolu daba lufana nokwenzeka kokushisisa okumazombezombe. Lapho i-motor isetshenziswa ku-voltage ephansi isikhathi eside, yamanje izokhula kakhulu. Ngokuvumelana nalokho, intambo eholayo kufanele futhi ikwazi ukumelana nomsinga omkhulu. Ikakhulukazi, lapho i-diameter yentambo eholayo ingenkulu ngokwanele, ukuminyana okuphezulu kwamanje kuzoholela ekushiseni kwentambo yomthofu.

(D) Indaba yokushisisa ezintanjeni zomthofu we-rotor. Lolu daba luhlukile kuma-rotor motors. Imbangela eyinhloko yento yokushisa ingase ibangelwe izici ezihlukahlukene, okuhlanganisa ukushiselwa kocingo oluholayo, ukuxhunywa kwendandatho yokuqoqa, ukufanisa indandatho yokuqoqa kanye nebhulashi lekhabhoni, kanye nempahla ye-carbon brush ngokwayo. Ngaphezu kwalokho, kuyinkinga eyinkimbinkimbi. Kulolu hlobo lwe-motor, ukungena komoya kanye nokuchithwa kokushisa kwendandatho yokuqoqa kubaluleke kakhulu. Izinga lokushisa lezindawo ezintathu zamaringi ainjini yezigaba ezintathuindandatho yomqoqi ihluka kakhulu, ebuye ithinte izinga lokushisa lokuhola kwe-rotor. Kodwa-ke, izinga lethonya liyahlukahluka kusuka kumotho kuya kwenye.

(E) Impahla kanye nokuhlanzwa kwetheminali nakho kufanele kubhekwe. Ngaphezu kweqhaza lazo ekuvikeleni izintambo zokuhola kanye nebhodi letheminali, amatheminali aholayo enjini kufanele futhi abonise ukuhamba kahle kukagesi. Uma i-terminal material ingeyekhwalithi embi, ngaphezu kwamandla okuphuka phakathi nenqubo yokufaka, inkinga ebaluleke kakhulu ukuthi ukumelana nokuxhumana kwengxenye yokuxhuma kuzokwanda, okuholela emazingeni okushisa aphakeme ocingweni lokuhola. Ngaphezu kwalokho, upende oyinsalela kutheminali, okungase kubangele ukuthi intambo yomthofu icwiliswe kupende kanye nokujikajika, kungabangela ukumelana kwendawo ukuthi kube kukhulu kakhulu, ngaleyo ndlela kuholele enkingeni yokushisisa entanjeni yomthofu.

(F). Ukwakheka kwe-terminal block akunangqondo. Uma ukwakheka kwe-terminal block kuthathwa njengokungafaneleki, kungenzeka ukuthi izingxenye zokuxhuma zizoxegiswa ngesikhathi sokusebenza kwenjini, okungase kubangele izintambo eziholayo kanye nama-windings ashise ngokweqile.

Ngenxa yokuhlaziywa okukhulunywe ngakho ngenhla, kubalulekile ukuqinisekisa ukuthembeka kokusebenza kwemikhiqizo yezimoto ngokusebenzisa ukukhetha okuqinile, ukulungiswa, kanye nenqubo yokulungisa elandelayo yezintambo eziholayo. Le ndlela ibalulekile ukuvimbela ukulimala okungenzeka kwayo yonke injini ngenxa yokwehluleka kwendawo.

Isikhathi sokuthumela: Oct-30-2024